The braking system is one of the most important components of a vehicle. Without reliable brakes, drivers cannot safely stop, increasing the chances of an accident. Proper vehicle maintenance includes checking the brake pads and shoes, and replacing them as necessary.

When buying brake disc pads and shoes, buyers should have a basic understanding of how brakes work, as well as the important differences between disc and drum brakes.

Understanding How Brakes Work

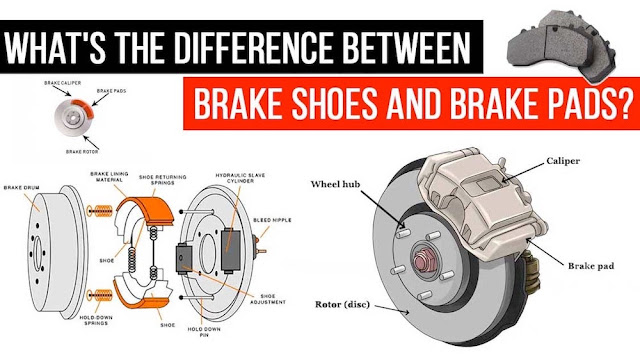

When drivers press the brake pedal, they engage the hydraulic system. This system forces fluid through a series of tubes and hoses that run from the brake's master cylinder to the piston, which applies pressure to the wheels and stops the car.

Some brakes use a system of discs and brake pads to accomplish this, while others use shoes and drums. Most passenger vehicles have a combination of disc and drum brakes, with disc brakes attached to the front wheels and drum brakes attached to the rear wheels.

Disc Brakes

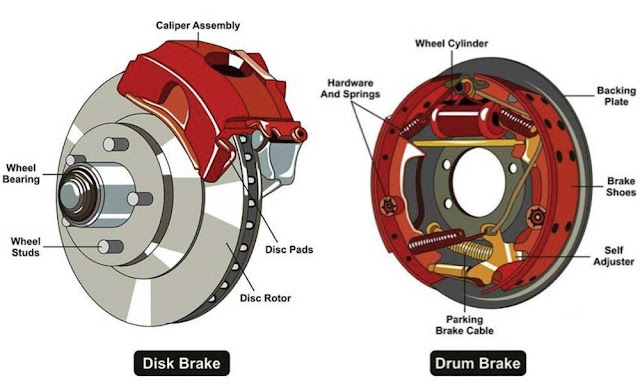

Disc brakes are pieces of flat, disc-shaped metal that spin with the wheels on the vehicle. They use calipers to squeeze the rotor, which in turn stops the vehicle. Manufacturers used to install disc brakes only on high-end vehicles; however, they now use them as front brakes on passenger vehicles because braking places tremendous pressure on the front of the car or truck. Disc brakes handle this pressure more efficiently and safely.

Brake Pads

Disc brakes have small blocks called pads that rest on the rotor attached to the vehicle's wheel. The caliper squeezes them to stop the turning motion of the wheel. When these pads wear thin, the brakes do not function well, and drivers must replace them.

Drum Brakes

Drum brakes are round cylinders that house the brake components. When a driver presses the brake pedal, the brake shoes apply pressure to the inside of the drum, which then slows the wheel until it stops. Until the mid-1990s, passenger car manufacturers placed drum brakes on all four wheels of the vehicle because they are relatively inexpensive to produce and easily incorporate emergency and parking brake systems. However, they are less efficient than disc brakes.

Brake Shoes

Drum brakes house all the parts of the brake within the bowl-shaped object that connects to the wheel. Instead of pads, these brakes have shoes inside that press against the inside of the drum to slow the wheels. Brake shoes wear over time and lose the ability to connect with the drum. When this happens, drivers must replace the shoes.

How to Choose Disc Pads / Brake Shoes for Armored Vehicle

The simplest way to choose disc pads and brake shoes is to replace them with products that match what the factory initially installed. However, some owners want to upgrade their pads and shoes to increase the life span or performance of the brakes.

Determine Which Type of Brakes are on the Armored Car

Most late model vehicles have disc brakes on the front and drum brakes on the rear wheels, but verifying this information is a simple process. Owners must either look through the wheels on their cars or remove the wheels to check the brakes. Disc brakes have a shiny smooth surface, while drum brakes are round, rough, and usually rusty.

Choose a Material

Manufacturers use different materials to produce brake pads and shoes, and these materials affect the feel and performance of the brakes. Towing equipment and driving at high speeds require pads and shoes that work well under high temperatures, while normal driving conditions give owners the option of choosing pads that make less noise and provide a more consistent feel during braking.

| Material | Advantages | Disadvantages |

| Ceramic | Quiet. Cause less damage to rotors. Long life span | More expensive than other materials. Not designed for all vehicles |

| Organic | Quiet. Safer than asbestos | Show signs of wear quickly |

| Semi-metallic | Last longer than organic material. Dissipate heat better. Work well under extreme driving conditions | Noisy. Produce more brake dust. Show signs of wear faster than ceramic materials |

Ceramic brake pads work well in oft-driven vehicles because they provide consistent pressure in all temperatures. Semi-metallic pads work well on heavier vehicles like trucks and in racing conditions that produce more heat, while organic pads function best on cars that are not subjected to extreme conditions.

Comments

Post a Comment